Sustraco Productions Services

We deliver high quality equipment and services to maximize and extend production for the life of the reservoir.

With more than 20 years of experience in the offshore and onshore market we offer services ranging from traditional equipment to advanced performance optimization to over 200 rigs around the world. We know when you need support.

ESP Rigless System

Efficient. Reliable. Exceptional Service.

The regular 300 Series of ESP System with a 2” or 2.1/2” Flexible hose has been designed to benefit the user in the long term by simplifying the work involved in installing and removing submersible pumps. There is no need a workover Rig for pump installation or retrieve, thus would cut your operation cost significantly.

Progressive Cavity Pump (PCP)

Supported by Oil lift-Canada

Advantages :

High System Efficiency (60-75) %

Wide Range to Produce High Viscosity Fluid (API, 5-45)

Ability to Produce large concentration of Sand

Ability to Tolerate High % of Free Gas

No Valve or Reciprocating Parts to Clog, Gas Locker or Wear

Good Resistance of Abrasion

Low Capital & Operating Cost

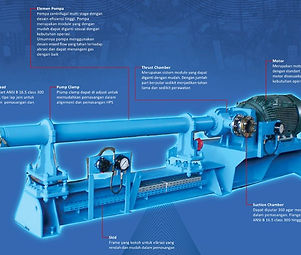

Hydraulic Jet Pump Technology

Fabricated in Indonesia-Supported by Experts

A hydraulic jet pump works effectively in a variety of down hole situations ranging from working in a deviated or crooked hole, to moving high solids and sand content. With NO MOVING PARTS DOWNHOLE, the Jet Pump System is the most attractive solution to operators working in unique situations where dependable, efficient and cost effective artificial lift is required

Production Well Testing & Separator

Customized to Your Preferences

At downstream we specialize in filling the needs of the petroleum industry, with products designed to withstand the rigors of oil and gas production. We understand that the ability to separate oil, gas, and water in oilfield operations is critical; that’s why we provide a wide range of robustly engineered 2 and 3 phase separators. Two phase separators are designed specifically for gas and oil, while 3 phase separators are designed for gas, oil, and water.

Scale & Paraffin Removal (SPR)

Efficient. Reliable. Exceptional Service.

SPR System Application is toPrevent your downhole well & Pipeline from Scale & Paraffin. Electromagnetic impact down to 6000 Ft and 15,000 Ft Lateral. Less maintenance, low voltage consumption

Applicable for all artificial lift except ESP system.

Automation System

Process visualization with Artificial lift Intelligence

Our SCADA system offers maximum functionality and a user-friendly user interface. With this configurable and scalable system, you have the advantage of absolute openness to both the office environment and to production. An integrated process database and Artificial lift Intelligence, for example, ensure transparency in production (downhole pressure, Temperature, Production Flow rate, Fluid Level, etc) . Numerous options and add-ons extend and expand the scope of performance.

Online Surface Production Maintenance

Wellhead & Valve Online & Onside Maintenance

SCOPE OF WORK

1.Valve Maintenance - Pumping Lubricant and Sealant to replace the existing Sealant in Ball Valve(s) as well as Gate Valve ( Well Head Valve )

2.On-line Repair : To Fix Up the Hard to Operate and Stuck Valve(s) in order to easy to Operate

3.To Replace bad Grease Fitting on a valve with the new one

4.To Replace Seat and Gate for Leaking Gate / Well Head Valve(s)

5.To Repair Actuator on SSV Well Head Valve

6.To Repair Actuator on SDV

Workshop & Repair Facility

Efficient. Reliable. Exceptional Service.

REPAIR FACILITY :

ESP CABLE REPAIR

ESP TEARDOWN FACILITY

GASLIFT REPAIR AND TESTING FACILITY

DOWNHOLE PUMP REPAIR

FABRICATION :

1. ESP HYDRAULIC CABLE SPOOLER

2. ESP VSD-TRANFORMER SKID

3. ESP OFFSHORE CABLE BASKET

4. ESP-PCP SWICTHBOARD & VSD

5. ESP TUBING HANGER (FUJI WORKSHOP)

6. PRESSURE VESSEL